Technical

EventSeries technical section is intended to be a useful guide to audio and broadcast cable related materials. Every effort has been made to ensure that it is user friendly and accurate but if you have any comments please email. This section will be updated periodically.

| SD-SDI(NTSC) | SD-SDI(PAL) | SD-SDI | SD_SDI | HD | 3 GHz | 3 GHz | 6 GHz | 12 GHz | |

|---|---|---|---|---|---|---|---|---|---|

| Data Rate | 143 Mb/s | 177 Mb/s | 270 Mb/s | 360 Mb/s | 1.5 Gb/s | 3 Gb/s | 3 Gb/s | 6 Gb/s | 12 Gb/s |

| Spec | SMPTE 259 | SMPTE 259 | SMPTE 259M | SMPTE 259M | SMPTE 292M (SMPTE 372M) | SMPTE 424M | SMPTE 425-4 | SMPTE ST 2081-1 | SMPTE ST 2082-1 |

| Application | Composite NTSC | Composite PAL | Composite 4:3 SD-SDI | Widescreen SD-SDI | 720p -1080i (Dual Link 1080p) | 3G-SDI HD-SDI 1080i 1.5G-SDI | UHDTV1 UHDTV2 | UHDTV1, UHDTV2 | UHDTV1, UHDTV2 |

| Part No. | Calculated Transmission Length [m] | Calculated Transmission Length [m] | Calculated Transmission Length [m] | Calculated Transmission Length [m] | Calculated Transmission Length [m] | Calculated Transmission Length [m] | Calculated Transmission Length [m] | Calculated Transmission Length [m] | Calculated Transmission Length [m] |

| HD300 | 152 | 137 | 116 | 111 | 34 | 25 | 25 | 24 | 21 |

| HD600 | 333 | 306 | 254 | 213 | 70 | 50 | 95 | 66 | 44 |

| 4706 | 337 | 309 | 256 | 216 | 71 | 49 | 97 | 67 | 46 |

| HD720 | 484 | 441 | 357 | 297 | 96 | 64 | 129 | 86 | 53 |

| 4708 | 492 | 448 | 361 | 303 | 98 | 66 | 132 | 88 | 59 |

| HD850 | 400 | 345 | 280 | 246 | 71 | 48 | 96 | 63 | 38 |

| HD920 | 454 | 408 | 318 | 272 | 79 | 59 | 106 | 69 | 54 |

| HD920F | 454 | 408 | 318 | 272 | 79 | 59 | 106 | 69 | 54 |

| HD1000 | 588 | 536 | 435 | 361 | 116 | 78 | 156 | 105 | 69 |

| 4710 | 612 | 566 | 455 | 385 | 124 | 83 | 165 | 110 | 79 |

| HD1300 | 581 | 520 | 433 | 372 | 144 | 120 | 192 | 128 | 81 |

| 4713T | 675 | 620 | 521 | 459 | 150 | 104 | 210 | 143 | 99 |

| HD1630 | 909 | 833 | 682 | 588 | 177 | 122 | 244 | 170 | 110 |

| 4716T | 938 | 882 | 714 | 612 | 182 | 129 | 258 | 184 | 117 |

| Application | Composite Video FBAS | S-Video S-VHS,Y/C | Component Video RGB , YUV | |

|---|---|---|---|---|

| Part No. | Attenuation 100 MHz/100m | Calculated Transmission Length [m] | Calculated Transmission Length [m] | Calculated Transmission Length [m] |

| HD300 | 22 dB | 50 | 50 | 50 |

| HD600 | 10 dB | 121 | 121 | 121 |

| HD720 | 7.5 dB | 149 | 149 | 149 |

| HD850 | 9.8 dB | 105 | 105 | 105 |

| HD1000 | 6.4 dB | 208 | 208 | 208 |

| HD1300 | 4.7 dB | 320 | 320 | 320 |

| HD1630 | 4.2 dB | 329 | 329 | 329 |

The calculated transmission distances are based on a formula in the SMPTE standards , in many cases tested distances are greater.

Please use calculated distances prior to testing and allow sufficient headroom.

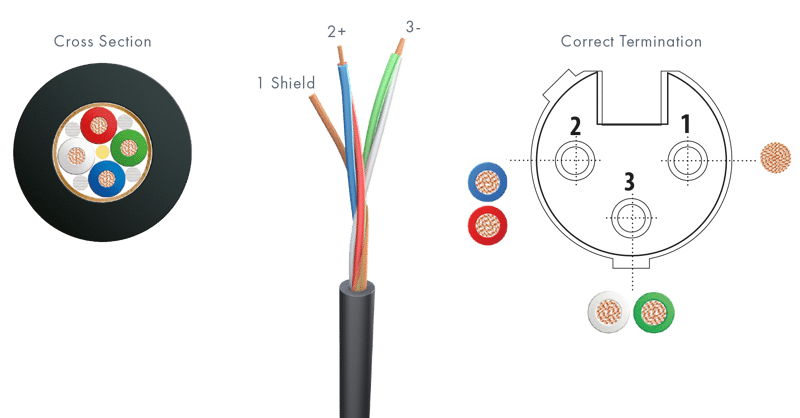

To properly wire a balanced to balanced cable using 4-conductor Starquad and maximise noise rejection opposing conductors are terminated together into an XLR-3 connector or terminal block.

In this example where the BBC standard colour code is used Blue & Red (+ Positive Phase) are wired together forming one half of the balanced pair and Green & White (- Negative Phase) are wired together forming the other half. Some starquad cables use two white conductors for the positive and two blue cores for the negative.

Starquad cables are four conductor cables which are all insulated and twisted together on a common axis. This “quad” construction or double balanced pairing reduces the chances of electromagnetically induced noise.

As the diagram below shows , the four conductors are arranged in a cross formation ,the conductors opposites are wired together in parallel to form a single balanced pair .The signals are sent out of phase with one another and then returned at the destination. The interference collected along the cable length is also then inverted, so put out of phase and made silent.

The outer screen helps to prevent electrostatic interference from reaching the signal cores.

| Pin | Signal | Core Colours |

|---|---|---|

| Pin 1 | (Shield - Chassis Ground) | |

| Pin 2 | Positive “hot” signal | Blue & Red |

| Pin 3 | Negative “cold” signal | Green & White |

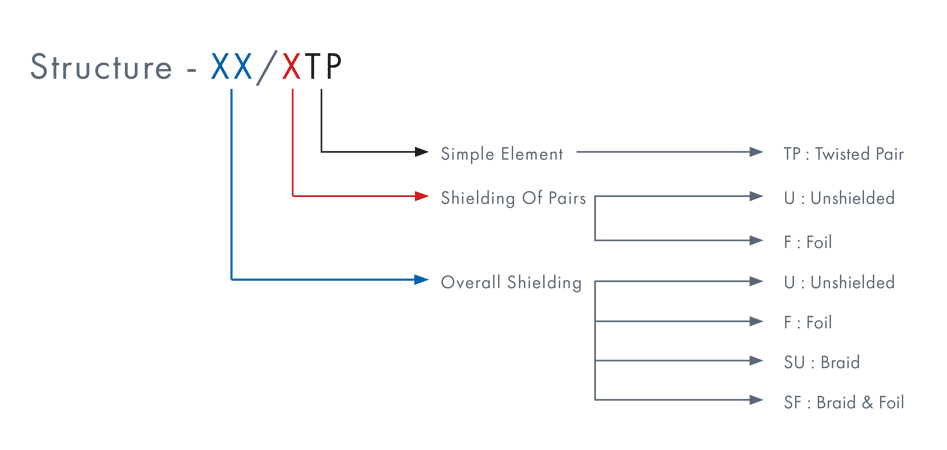

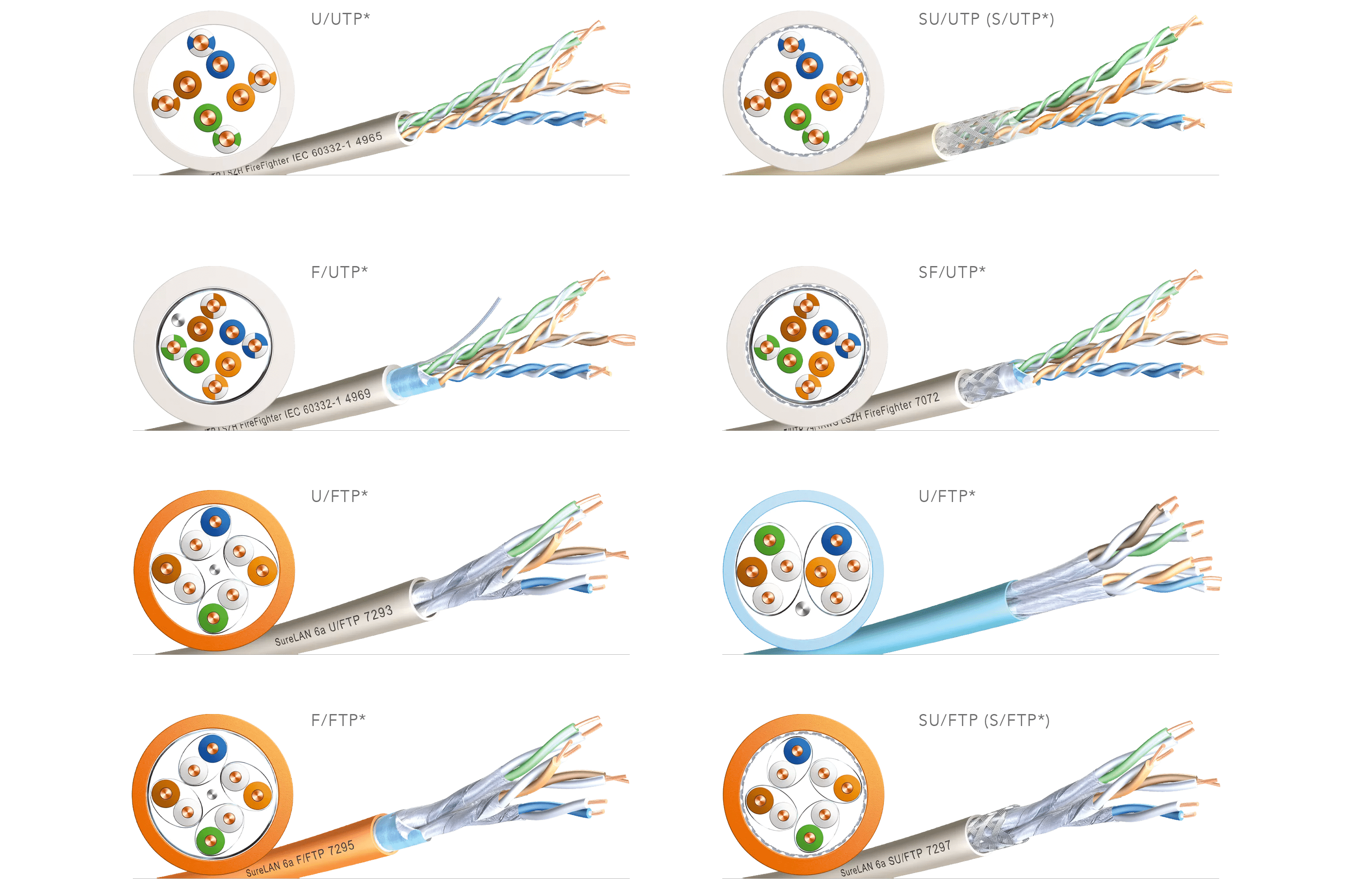

| Structure (*ISO/IEC 11801) | Description |

|---|---|

| U/UTP* | Unshielded twisted pairs |

| SU/UTP (S/UTP*) | Overall braid screen with unscreened twisted pairs |

| F/UTP* | Overall foil shielded twisted pairs |

| SF/UTP* | Overall foil & Overall braid shielded twisted pairs |

| U/FTP* | Individual foil shielded twisted pairs |

| U/FTP* | Alternate shield type lay up as 2x2pairs , each 2pair has a shield |

| F/FTP* | Individual foil and overall foil shielded pairs |

| SU/FTP (S/FTP*) | Individual foil and overall braid shielded twisted pairs |

Class 1 & 2: Shows the obligatory number of strands

Class 5 & 6: Shows the maximum strand diameter, may be fewer strands as long as the maximum ohms/km is not exceeded

Ohms Ω/km: Shows the maximum resistance in that is permissible for untinned copper conductors in the stranding classes indicated

| Area mm² | Stranding Class 1 | Stranding Class 2 | Ohms Ω/km | Stranding Class 5 | Stranding Class 6 | Ohms Ω/km | |

|---|---|---|---|---|---|---|---|

| 0.14 | 18 x 0.10 | 18 x 0.10 | 138.0 | ||||

| 0.25 | 14 x 0.16 | 32 x 0.10 | 79.0 | ||||

| 0.34 | 19 x 0.16 | 42 x 0.10 | 57.0 | ||||

| 0.5 | 1 x 0.80 | 7 x 0.30 | 36.0 | 16 x 0.21 | 28 x 0.10 | 39.0 | |

| 0.75 | 1 x 0.97 | 7 x 0.37 | 24.5 | 24 x 0.21 | 42 x 0.16 | 26.0 | |

| 1.0 | 1 x 1.13 | 7 x 0.43 | 18.1 | 32 x 0.21 | 56 x 0.16 | 19.5 | |

| 1.5 | 1 x 1.38 | 7 x 0.53 | 12.1 | 30 x 0.26 | 84 x 0.16 | 13.3 | |

| 2.5 | 1 x 1.78 | 7 x 0.67 | 7.41 | 50 x 0.26 | 140 x 0.16 | 7.98 | |

| 4.0 | 1 x 2.26 | 7 x 0.85 | 4.61 | 56 x 0.31 | 224 x 0.16 | 4.95 | |

| 6.0 | 1 x 2.76 | 7 x 1.04 | 3.08 | 84 x 0.31 | 192 x 0.21 | 3.30 | |

| 10.0 | 1 x 3.57 | 7 x 1.35 | 1.83 | 80 x 0.41 | 320 x 0.21 | 1.91 | |

| 16.0 | 1 x 4.51 | 7 x 1.70 | 1.15 | 128 x 0.41 | 512 x 0.21 | 1.21 | |

| 25.0 | 7 x 2.14 | 0.72 | 200 x 0.41 | 800 x 0.21 | 0.78 | ||

| 35.0 | 7 x 2.52 | 0.524 | 280 x 0.41 | 1120 x 0.21 | 0.554 | ||

| 50.0 | 19 x 1.78 | 0.387 | 400 x 0.41 | 705 x 0.31 | 0.386 | ||

| 70.0 | 19 x 2.14 | 0.268 | 356 x 0.51 | 990 x 0.31 | 0.272 | ||

| 95.0 | 19 x 2.52 | 0.193 | 485 x 0.51 | 1340 x 0.31 | 0.206 | ||

| 120 | 37 x 2.03 | 0.153 | 614 x 0.51 | 1690 x 0.31 | 0.161 | ||

| 150 | 37 x 2.25 | 0.124 | 765 x 0.51 | 2123 x 0.31 | 0.129 | ||

| 185 | 37 x 2.52 | 0.099 | 944 x 0.51 | 1470 x 0.41 | 0.106 | ||

| 240 | 61 x 2.25 | 0.074 | 1225 x 0.5 | 1905 x 0.41 | 0.081 | ||

| 300 | 61 x 2.52 | 0.060 | |||||

| 400 | 61 x 2.85 | 0.046 | |||||

| 500 | 61 x 3.20 | 0.036 |

NOTES:

1. Construction: C – Concentric; U – Unilay; R – Ropelay

2. Change of 3 AWG Numbers Doubles Resistance and Halves Weight

3. Properties of Copper:

a) Tensile Strength: Hardened copper: 478 N/mm² (47.8kgf/mm²) Annealed Copper: 239 N/mm² (23.9kgf/mm²)

b) Average Resistivity: 1.7241 microhm-cm at 20°C

| AWG | CONSTRUCTION | DIAMETER (mm) | AREA (mm²) | WEIGHT (g/m) | R Ω max (Ω/100m) at 20°C |

|---|---|---|---|---|---|

| 4 | 133 x 0.455 R | 6.48 | 21.62 | 197.9 | 0.09 |

| 6 | 133 x 0.361 R | 5.14 | 13.61 | 124.9 | 0.14 |

| 8 | 1 x 3.26 | 3.26 | 8.37 | 74.38 | 0.21 |

| 133 x 0.287 R | 4.09 | 8.6 | 79.02 | 0.22 | |

| 10 | 1 x 2.59 | 2.59 | 5.26 | 46.77 | 0.35 |

| 37 x 0.404 C | 2.8 | 4.77 | 44.43 | 0.38 | |

| 91 x 0.254 U | 2.7 | 4.61 | 42.22 | 0.43 | |

| 12 | 1 x 2.05 | 2.05 | 3.31 | 29.46 | 0.55 |

| 19 x 0.455 C | 2.27 | 3.09 | 28.66 | 0.59 | |

| 37 x 0.320 C | 2.22 | 2.98 | 27.88 | 0.61 | |

| 45 x 0.300 C | 2.45 | 3.18 | 28.27 | 0.58 | |

| 91 x 0.203 U | 2.15 | 2.95 | 27 | 0.65 | |

| 13 | 1 x 1.83 | 1.83 | 2.63 | 23.36 | 0.7 |

| 14 | 1 x 1.63 | 1.63 | 2.08 | 18.45 | 0.88 |

| 19 x 0.361 C | 1.8 | 1.94 | 18.04 | 0.94 | |

| 19 x 0.361 U | 1.7 | 1.94 | 17.14 | 0.94 | |

| 27 x 0.300 C | 1.8 | 1.91 | 16.98 | 0.94 | |

| 37 x 0.254 C | 1.78 | 1.88 | 16.67 | 0.97 | |

| 61 x 0.203 U | 1.76 | 1.97 | 18.5 | 1.04 | |

| 15 | 1 x 1.45 | 1.45 | 1.65 | 14.68 | 1.11 |

| 16 | 1 x 1.29 | 1.29 | 1.31 | 11.62 | 1.4 |

| 19 x 0.287 C | 1.42 | 1.23 | 11.41 | 1.49 | |

| 19 x 0.287 U | 1.36 | 1.23 | 10.83 | 1.49 | |

| 19 x 0.300 C | 1.5 | 1.34 | 12.5 | 1.36 | |

| 19 x 0.300 U | 1.43 | 1.34 | 11.86 | 1.36 | |

| 61 x 0.16 U | 1.45 | 1.23 | 11.23 | 1.45 | |

| 315 x 0.071 R | 1.6 | 1.25 | 11.8 | 1.47 | |

| 17 | 1 x 1.15 | 1.15 | 1.04 | 9.24 | 1.76 |

| 18 | 1 x 1.02 | 1.02 | 0.824 | 7.32 | 2.22 |

| 7 x 0.404 | 1.21 | 0.901 | 8.25 | 2.03 | |

| 19 x 0.254 C | 1.27 | 0.962 | 8.93 | 1.9 | |

| 19 x 0.254 U | 1.21 | 0.962 | 8.49 | 1.9 | |

| 61 x 0.142 U | 1.24 | 0.966 | 9 | 1.89 | |

| 19 | 1 x 0.91 | 0.91 | 0.653 | 5.8 | 2.8 |

| 20 | 1 x 0.813 | 0.813 | 0.518 | 4.61 | 3.53 |

| 7 x 0.320 | 0.96 | 0.563 | 5.17 | 3.25 | |

| 19 x 0.203 C | 1.009 | 0.616 | 5.7 | 2.97 | |

| 19 x 0.203 U | 0.966 | 0.616 | 5.42 | 2.97 | |

| 37 x 0.142 U | 0.97 | 0.586 | 5.38 | 3.12 | |

| 135 x 0.071 | 0.92 | 0.534 | 4.9 | 3.42 | |

| 21 | 1 x 0.724 | 0.724 | 0.412 | 3.66 | 4.44 |

| 22 | 1 x 0.643 | 0.643 | 0.324 | 2.89 | 5.64 |

| 7 x 0.254 | 0.762 | 0.355 | 3.26 | 5.15 | |

| 19 x 0.160 C | 0.8 | 0.382 | 3.55 | 4.78 | |

| 19 x 0.160 U | 0.762 | 0.382 | 3.37 | 4.78 | |

| 37 x 0.114 U | 0.78 | 0.38 | 3.46 | 4.83 | |

| 72 x 0.071 | 0.68 | 0.285 | 2.6 | 6.41 | |

| 23 | 1 x 0.574 | 0.574 | 0.259 | 2.3 | 7.06 |

| 24 | 1 x 0.511 | 0.511 | 0.205 | 1.82 | 8.91 |

| 7 x 0.203 | 0.609 | 0.227 | 2.08 | 8.05 | |

| 19 x 0.127 C | 0.634 | 0.241 | 2.23 | 7.58 | |

| 19 x 0.127 U | 0.597 | 0.241 | 2.12 | 7.58 | |

| 56 x 0.071 U | 0.6 | 0.222 | 2.05 | 8.23 | |

| 25 | 1 x 0.455 | 0.455 | 0.163 | 1.44 | 11.24 |

| 26 | 1 x 0.404 | 0.404 | 0.128 | 1.14 | 14.26 |

| 7 x 0.160 | 0.48 | 0.141 | 1.29 | 12.96 | |

| 19 x 0.102 C | 0.504 | 0.155 | 1.44 | 11.79 | |

| 19 x 0.102 U | 0.483 | 0.155 | 1.37 | 11.79 | |

| 33 x 0.071 U | 0.45 | 0.13 | 1.2 | 14.06 | |

| 27 | 1 x 0.320 | 0.361 | 0.102 | 0.91 | 17.86 |

| 28 | 1 x 0.320 | 0.32 | 0.08 | 0.72 | 22.72 |

| 7 x 0.127 | 0.381 | 0.089 | 0.82 | 20.6 | |

| 19 x 0.079 C | 0.395 | 0.093 | 0.86 | 19.63 | |

| 29 | 1 x 0.287 | 0.287 | 0.065 | 0.58 | 28.25 |

| 30 | 1 x 0.254 | 0.254 | 0.051 | 0.45 | 36.07 |

| 7 x 0.102 | 0.304 | 0.057 | 0.53 | 31.95 | |

| 19 x 0.063 C | 0.315 | 0.059 | 0.57 | 30.87 | |

| 31 | 1 x 0.226 | 0.226 | 0.04 | 0.36 | 45.56 |

| 32 | 1 x 0.203 | 0.203 | 0.032 | 0.29 | 56.47 |

| 7 x 0.079 | 0.237 | 0.034 | 0.32 | 53.28 | |

| 19 x 0.050 C | 0.25 | 0.037 | 0.36 | 49 | |

| 33 | 1 x 0.180 | 0.18 | 0.025 | 0.23 | 71.82 |

| 34 | 1 x 0.160 | 0.16 | 0.02 | 0.18 | 90.9 |

| 7 x 0.063 | 0.189 | 0.022 | 0.21 | 83.8 | |

| 35 | 1 x 0.142 | 0.142 | 0.016 | 0.14 | 115.4 |

| 36 | 1 x 0.127 | 0.127 | 0.0127 | 0.11 | 144.3 |

| 7 x 0.050 | 0.15 | 0.0137 | 0.13 | 133.4 | |

| 37 | 1 x 0.114 | 0.114 | 0.0102 | 0.09 | 179 |

| 38 | 1 x 0.102 | 0.102 | 0.0081 | 0.07 | 225 |

| 7 x 0.040 | 0.12 | 0.0088 | 0.0784 | 214 | |

| 39 | 1 x 0.089 | 0.089 | 0.00622 | 0.06 | 295 |

| 40 | 1 x 0.079 | 0.079 | 0.0049 | 0.0436 | 375 |

| 7 x 0.031 | 0.09 | 0.00528 | 0.0469 | 350 | |

| 41 | 1 x 0.071 | 0.071 | 0.00396 | 0.0352 | 460 |

| 42 | 1 x 0.063 | 0.063 | 0.00316 | 0.0281 | 600 |

| 7 x 0.025 | 0.075 | 0.0034 | 0.0318 | 536 | |

| 43 | 1 x 0.056 | 0.056 | 0.00246 | 0.0219 | 745 |

| 44 | 1 x 0.050 | 0.05 | 0.00203 | 0.018 | 910 |

| 7 x 0.020 | 0.06 | 0.0022 | 0.0196 | 836 | |

| 46 | 1 x 0.040 | 0.04 | 0.00126 | 0.0112 | 1500 |

| 7 x 0.015 | 0.045 | 0.001372 | 0.0112 | 1492 | |

| 48 | 1 x 0.031 | 0.031 | 0.00075 | 0.0067 | 2450 |

| 7 x 0.0125 | 0.0375 | 0.000859 | 0.0077 | 2371 | |

| 50 | 1 x 0.025 | 0.025 | 0.00049 | 0.0044 | 3750 |

| 7 x 0.0100 | 0.03 | 0.00055 | 0.0049 | 3872 | |

| 52 | 1 x 0.020 | 0.02 | 0.00031 | 0.0028 | 5850 |

| 54 | 1 x 0.0158 | 0.0158 | 0.000196 | 0.00175 | 10441 |

| 56 | 1 x 0.0125 | 0.0125 | 0.000123 | 0.00109 | 16599 |

| 58 | 1 x 0.0100 | 0.01 | 0.000079 | 0.0007 | 27101 |